During the 3rd National Photonics Technology Forum held in Guangzhou from March 31st to April 3rd, 2023, Professor Wang Yiping's team from Shenzhen University and Shenzhen Photon Sensing Technology Co., Ltd. made the domestic debut of large-scale Fiber Bragg Grating Array Femtosecond Laser Fully Automated Fabrication Technology, equipment, and array products.

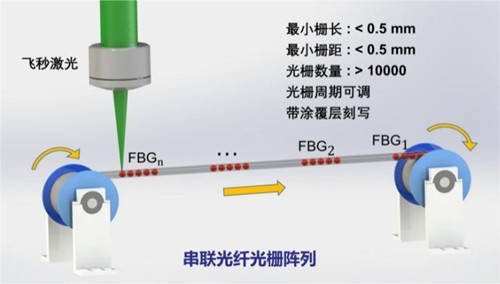

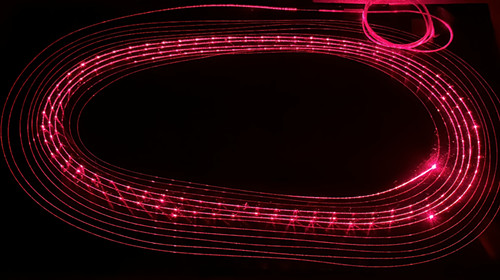

This technology enables the efficient fully automated fabrication of kilometer-scale, roll-to-roll large-scale serial/parallel integrated fiber Bragg grating arrays (including weak reflection points) in both single-core and multi-core fibers. It boasts advantages such as direct writing with coating, no need for mask templates, no need for hydrogen loading, and no need for secondary coating. Moreover, it achieves full automation of the fiber movement, clamping, feeding, collecting, core alignment, laser focusing, exposure, and other processes involved in grating fabrication. The fabricated fiber Bragg grating arrays retain the original fiber's tensile strength, high temperature resistance, and long-term stability.

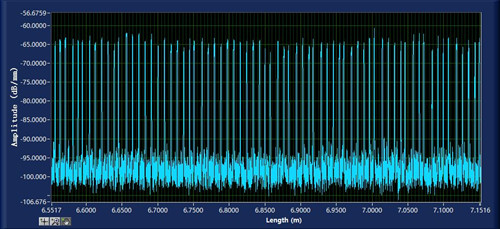

The on-site presentation featured large-scale identical weakly reflective fiber Bragg grating arrays with a grating wavelength of 1550 nm, minimum grating length of < 0.5 mm, minimum grating spacing of < 0.5 mm, minimum reflectivity of < one hundred thousandth, over 10,000 gratings, and an extinction ratio of 15 dB.

Parameters such as grating wavelength, reflectivity, spacing, and quantity can be customized according to user requirements. This large-scale fiber Bragg grating array has wide-ranging applications in distributed fiber sensing fields such as oil well exploration, perimeter security, bridge and dam monitoring, aerospace, and aviation. It can significantly enhance the measurement accuracy, distance, and spatial resolution of distributed fiber sensing technologies such as DAS, DTS, OFDR, making it a "booster" for distributed fiber sensing technology.

![]() Add : No. 3688, Nanhai Avenue, Nanshan District, Shenzhen, Guangdong Province

Add : No. 3688, Nanhai Avenue, Nanshan District, Shenzhen, Guangdong Province ![]() Email : cpoe@szu.edu.cn

Email : cpoe@szu.edu.cn ![]() Phone: 0755-26538735

Phone: 0755-26538735 ![]() Fax : 0755-26538735

Fax : 0755-26538735